Carrying out large-scale reconstruction and expansion work for the future

It has been announced that Porsche is investing approximately 250 million euros to newly upgrade the Zuffenhausen factory, Porsche's main production plant.

In the future, the 718 model, which will be a fully electric vehicle, will also be produced at the Zuffenhausen plant.

The factory will be upgraded to become more efficient than ever before, and above all, it will become a ``smart factory,'' which will allow internal combustion engine sports cars and EV sports cars to be produced in the same factory.

It is said to be the beginning of a new chapter in sports car production for Porsche.

During the construction process, many sports car production systems will be upgraded, and the production process will be further developed.

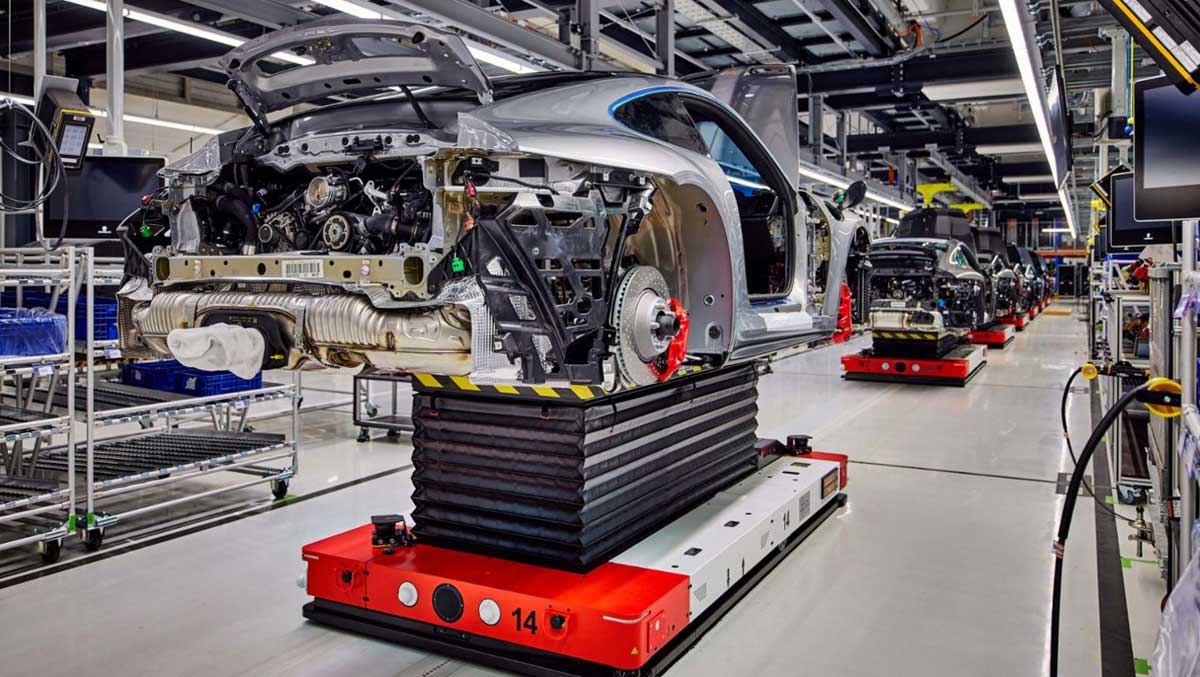

Production using unmanned self-driving guided vehicles

Porsche has expanded the production line area at its Zuffenhausen factory and introduced the latest automated guided vehicles (Automated Guided Vehicles (AGVs)), which will also be used to produce two-door sports cars like the Taycan. yes.

The latest generation of AGVs enables even more diverse production processes by replacing traditional assembly lines with ``Flexilines'', which allow mixed production of vehicles with internal combustion engines and electric powertrains on a single line. seems to be becoming possible.

Assembly of the electric powertrain for the EV Macan will also be integrated into the existing engine factory.

Newly integrated quality checkpoint

The aim of the factory improvements is to increase Porsche's production process capabilities and flexibility. Production has also been expanded to include additional quality test benches for vehicle assembly, an additional logistics area and a new high-bay rack. To.

Quality control during the production process has also been further refined, with a new assembly process and a new quality assurance station.

Following the principle of a first-time quality approach with small control loops, standardized quality assurance and approval checkpoints are integrated into the production process, with individual checkpoint management starting at the end of the assembly process.

Various processes have been adopted to ensure optimal vehicle inspection, most notably the installation of a new light tunnel.

The finishing area now offers a clearer process structure and upgraded test procedures, including adapting the acoustic test bench to electric vehicle requirements.

All of the test benches used for surface inspection and leakage inspection have also been improved.

The Zuffenhausen factory's logistics area has been expanded since 2022, with the addition of a new building on the site of the former Porsche Center opposite the Porsche Museum.

The entire renovation is scheduled to be completed in 2025, but once completed, parts will be shared with the body shop that produces Taycan and sports cars using a high-bay rack that spans two floors. It is said that it will happen.

The new high bay rack, which was already opened in September 2023, is said to be supplying various parts to the entire assembly plant, and the parts warehouse is fully automated.

The storage capacity is approximately 2,000 tons and 35,000 cubic meters. This is equivalent to storage space for 40,650 pallets and containers.

Since 2016, a new assembly plant for V8 engines for the Panamera and Cayenne models has been built at the Zuffenhausen plant, and now electric motors for the electric Macan are also assembled at the Zuffenhausen engine production center. It seems that production of the new generation Macan from 2024 will change from the Leipzig factory to the Zuffenhausen factory.

Source:(Official) Porsche upgrades Zuffenhausen production plant for the future